Our plastic injection molding process produces custom prototypes and end-use production parts. We use steel or aluminum molds offering cost-effective tooling and accelerated manufacturing cycles, and stock many different thermoplastic resins.

We are ISO-2015 certified.

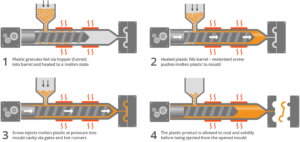

The thermoplastic injection molding process is a standard process involving a mold with cooling lines running through it, which means cycle times are a quicker. It allows our molders to monitor fill pressure, cosmetic concerns, and the basic quality of the parts.

Resin pellets are loaded into a barrel where they will eventually be melted, compressed, and injected into the mold’s runner system. Hot resin is shot into the mold cavity through the gates and the part is molded. Ejector pins facilitate removal of the part from the mold where it falls into a loading bin. When the run is complete, parts (or the initial sample run) are boxed and shipped shortly thereafter.

Our automated packaging systems helps us get your product polybagged and/or boxed, then onto gaylords using either plain white or custom printed boxes. Our team works with you to ensure all artwork is exactly the way you or your customers need it.

In addition, we create custom labels whether white or graphical, designed to your specifications.

We can heat shrink or use master cartons depending on your requirements.

Here at Ramcoa our customers know once the order is placed and confirmed, it will be delivered on time every time.

Ramcoa will get you through the process from design to manufacture.

1130 West Elizabeth Ave

Linden NJ 07036

Tel: 908.862.6744

Fax 908.862.6747

Inquiries: [email protected]